Adoption Center für Binder Jetting (additive Fertigung) in Europa

Unser Team im European Adoption Center ist darauf spezialisiert, Herausforderungen bei der Herstellung komplexer Teile aus Pulverwerkstoffen wie Metallen, technischen Keramiken oder auch Graphit, Sanden und Salzen zu lösen.

Wir möchten Sie ermutigen, die Zusammenarbeit mit uns zu suchen, um die mit der Einführung der additiven Fertigung verbundenen Risiken zu minimieren.

Wir sind uns bewusst, dass Hersteller wie Sie trotz der potenziellen Vorteile der additiven Fertigung aufgrund einer Kombination aus technischen, finanziellen und betrieblichen Herausforderungen zögern können, diese einzuführen. Aus diesem Grund ist das European Adoption Center (EAC) von ExOne hier, um Ihnen zu helfen, Ihre Vorbehalte und Hindernisse bei der Einführung des 3D-Drucks zu überwinden.

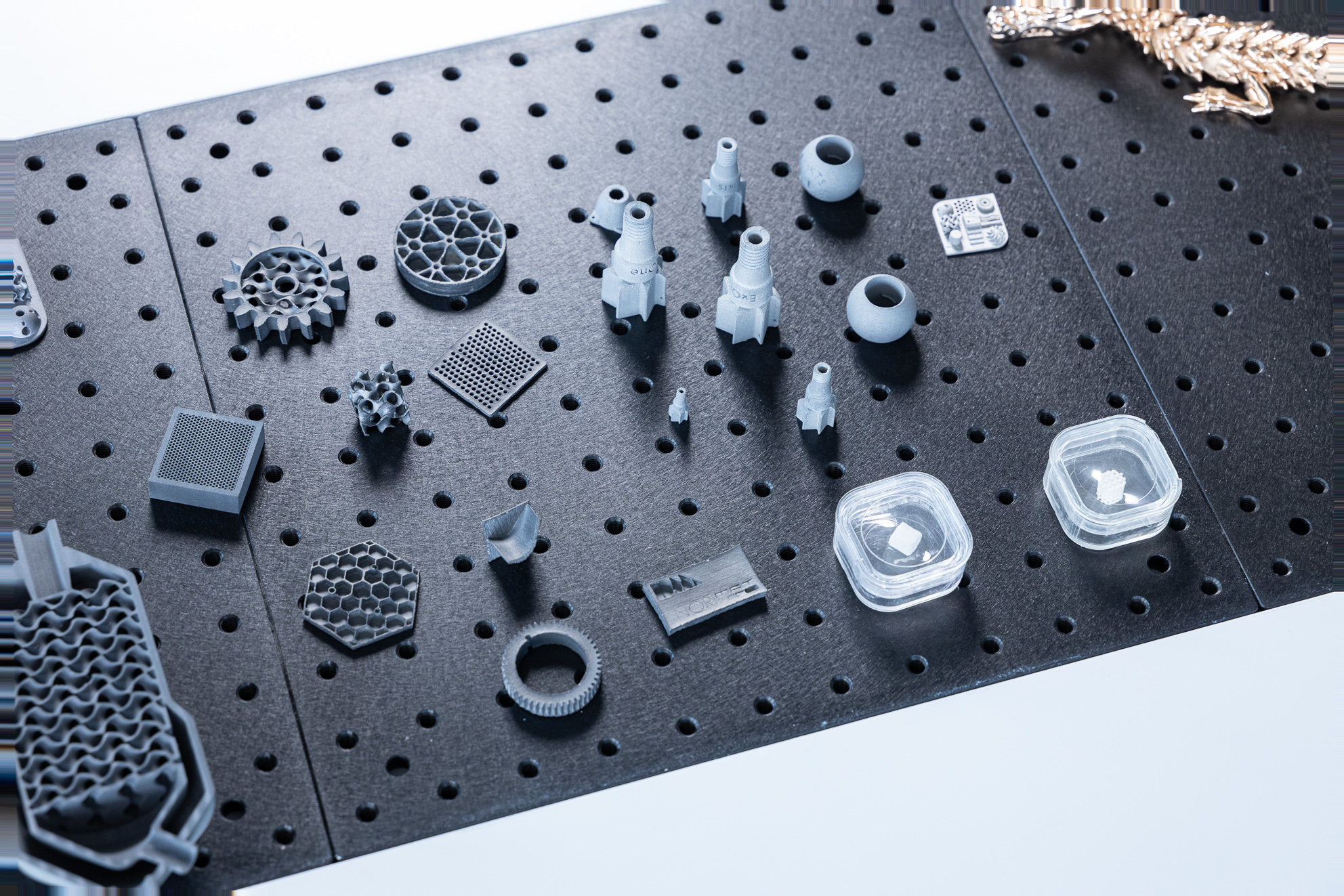

Das EAC unterstützt seine Kunden dabei, das Potenzial des Binderjet-3D-Drucks für ihre einzigartigen Designs und Materialien zu erkunden. Das EAC bietet Unternehmen eine risikoarme Möglichkeit, diese transformative Technologie zu evaluieren, bevor sie in ein eigenes additives Fertigungssystem investieren. Das EAC bietet eine umfassende Palette an Lösungen und Dienstleistungen für die additive Fertigung (AM), um Unternehmen zu unterstützen, AM erfolgreich in ihre Fertigungsprozesse zu integrieren.

Das EAC baut auf dem etablierten Sand 3D Printing Adoption Center von ExOne in Gersthofen, Deutschland, auf, das sich auf die Herstellung von Sandformen und -kernen für den Metallguss spezialisiert hat. Das EAC erweitert nun seine Fähigkeiten um den direkten Binderjet-3D-Druck komplexer Teile aus einer Vielzahl von Materialien. Die Hersteller erhalten Zugang zu umfassenden technischen Dienstleistungen, einschließlich Benchmarking, Designoptimierung sowie Material-, Prozess- und Arbeitszellenentwicklung mit bekannten oder neuen Materialien und Pulvern.

Das EAC ist mit der fortschrittlichen X-Serie skalierbarer 3D-Drucker von Desktop Metal ausgestattet, wie z. B. dem InnoventX™ und dem X25Pro™. Diese sind für ihre Kompatibilität mit einer breiten Palette von Materialien und Pulvern sowie mehreren Bindersystemen und Hardwarekonfigurationen bekannt.

Bei einer Zusammenarbeit profitieren Sie von folgenden Vorteilen:

- Minimierung von Lieferketten

- Schnellerer Ersatz komplexer Teile

- Effizientes Drucken komplexer Designs

- Herstellung von Leichtbaustrukturen

- Hohe Leistungsanforderungen werden erfüllt

- Konsolidierung von einzelnen Bauteilen für neue Effizienzsteigerungen

- Entwicklung neuer wettbewerbsfähiger Produktdesigns

Gerne stehen wir Ihnen bei der Bewältigung dieser Herausforderungen zur Seite und gewährleisten dabei stets die Einhaltung höchster Qualitäts- und Sicherheitsstandards.

.PNG?ext=.png)