Efficiency and Precision through Sand 3D Printing in Iron Casting

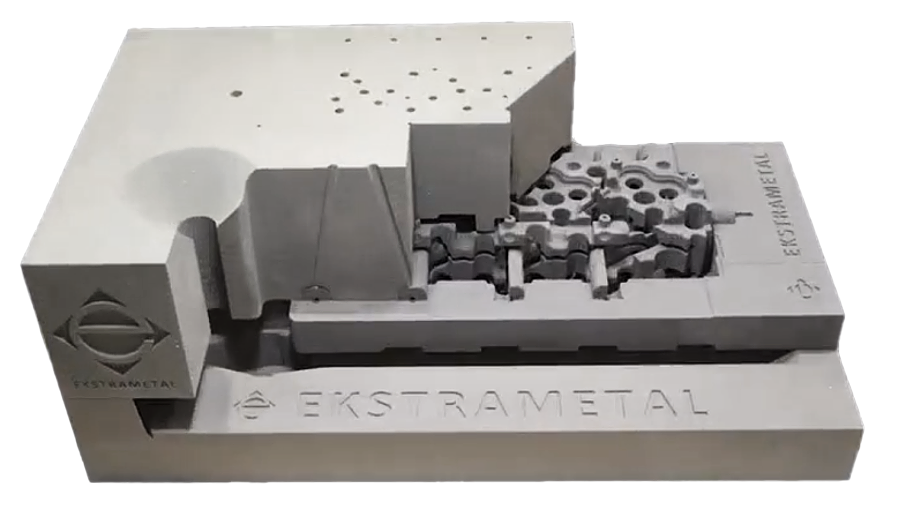

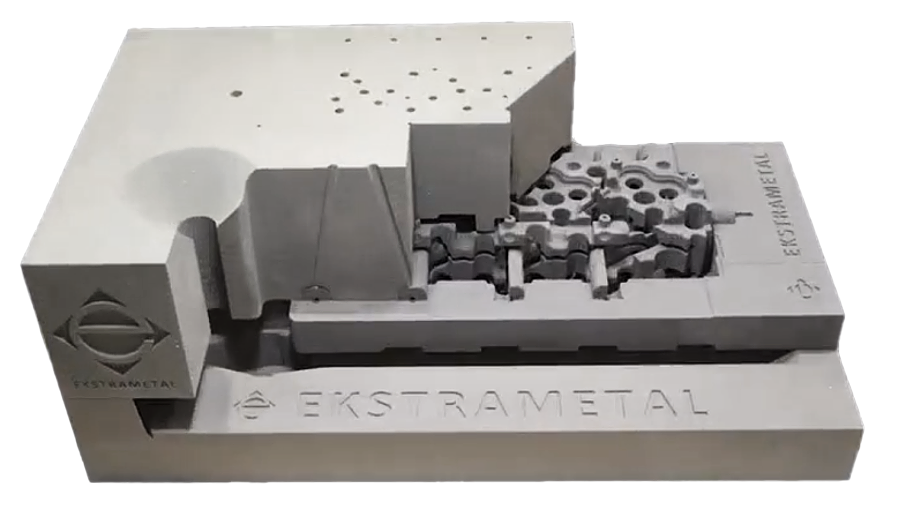

Ekstrametal, the first Turkish foundry to adopt sand binder jetting, delivers top-quality cast parts by 3D printing molds and cores.

Efficiency and Precision through Sand 3D Printing in Iron Casting

Ekstrametal, the first Turkish foundry to adopt sand binder jetting, delivers top-quality cast parts by 3D printing molds and cores.